By Jeff Spindler, Director of Product Commercialization

In late January, the U.S. Department of Energy (DOE) hosted its annual Solid-State Lighting (SSL) R&D Workshop in sunny San Diego. For us Rochestarians, this is a nice break from the wintry Northeastern weather. More importantly, this venue gives OLEDWorks an opportunity to interact with all the SSL industry players as well as academia, government agencies, and standards setting organizations.

OLEDWorks’ Presence at the R&D Workshop

Because of my role in managing government-funded projects, I am fortunate to be able to attend this workshop every year. OLEDWorks has benefited from several DOE-funded OLED research projects for the past 5 or 6 years. Without this funding, we would not have been able to make the rapid progress that we have in terms of improving OLED performance and reducing costs on our way to becoming the leading supplier of the highest quality OLED lighting panels. As such, we are grateful to the DOE for the continued support and confidence in our ability to deliver on project goals that translate into commercial products.

At this year’s workshop, Michael Boroson and I presented 3 posters at the poster session and gave 2 technical presentations: one on the state of OLED light extraction, and the other on OLED manufacturing and integration challenges.

OLED Light Extraction: Past, Present, Future

Today’s 85 LPW Brite3 OLED panels only extract about 50% of the photons that are generated within the device. With continued focused research on solving this challenging problem, future OLED panels could harvest 70-80% of the photons, resulting in efficacy of 130 LPW or higher. Unfortunately, many of the techniques used to improve light extraction for inorganic LEDs are not applicable to OLEDs, therefore new technologies are required.

Michael presented an excellent summary of past, present, and future work aimed at improving OLED extraction efficiency. Many companies and universities are researching various promising techniques to reduce unwanted absorption and wave guiding losses of the photons within the OLED stack. And OLEDWorks is working with most, if not all, of these institutions.

OLED and LED: Complementary Lighting Technologies

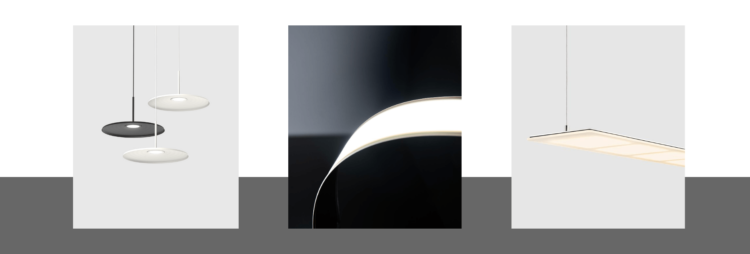

My presentation highlighted many of the contrasts between LEDs and OLEDs in terms of manufacturing and integration into luminaires. The bottom line is that OLED manufacturing is still at the early stages and there is much room for improvement to reduce costs. We cannot afford to build mega-factories like the display industry does, so we need to be smarter in how we make and scale production of OLED lighting panels. The great news is that even at this early lower volume stage, the integrated luminaire cost for OLEDs or hybrid OLED-LED fixtures can be very competitive with pure LED luminaires.

Every lighting designer should have OLED in their toolbox, realizing that LEDs and OLEDs can and should be used in a complementary and harmonious manner to maximize energy savings and reap the greatest human benefits, whether it be health, comfort, or productivity.

Continuous R&D Will Inevitably Improve Efficiency and Lower Cost of OLED

The poster session gave us the opportunity to share our great progress in critical R&D areas through DOE-funded projects aimed at improving efficiency and lowering the cost of future flexible OLED lighting panels (think “Wave2”). Some of the research on alternate anode materials like silver nanowires and alternate maskless production techniques won’t be employed in the near future, but advancements in flexible light extraction and color tunable OLEDs will likely show up in real OLED products soon.

One presentation by RTI highlighted the excellent reliability, lifetime, and color stability of our 6-stack white OLED lighting panels. This was an important unbiased validation to our product claims of long lifetime and unmatched reliability.

OLEDWorks Posters:

Commercialization of an Ultra-Thin, Bendable, High Efficacy OLED Light Engine – 2020

Mask-Free OLED Fabrication Process for Non-Tunable and Tunable OLEDs – 2020

SBIR Printed Anodes and Internal Extraction Layers on Flexible Glass – 2020

Imitation is the Sincerest Form of Flattery

Unlike previous years, this year I came away with the impression that OLED lighting was more of a mainstream topic and not just a side topic or curiosity. Many prominent luminaire manufacturers are acknowledging the fact that OLED light sources are very approachable and comfortable to look at due to the diffuse nature of the light. In fact, one significant trend in LED luminaire design is to use edge-lit LEDs with primary and secondary optics to diffuse the LED light and reduce the harsh glare that comes from shining bright LEDs directly into the viewers’ eyes. One might argue that they are trying to make the LED fixtures look more “OLED-like” in nature. This of course comes at a cost of reduced efficiency and higher component cost.

This was a prominent theme that echoed throughout the workshop – that OLED lighting is here, performance has improved tremendously, reliability is excellent, and it is ready for the market now.

As I was writing this blog post, I was excited to learn that OLEDWorks was just selected by the DOE for yet another award to improve OLED light extraction! Make sure you subscribe to the OLEDWorks blog to keep up with all of our exciting research and innovations.